“How can I ensure I get ROI from Mingo?” It’s a question we get frequently, and there are two ways to see ROI.

1. You can calculate ROI with formulas and numbers. Every business wants to see a return on the money invested, and an investment in manufacturing analytics is no different. Calculate yours with the ROI calculator.

2. You can also calculate ROI in terms of cultural benefits, employee engagement, project ownership, effective production meetings, and visibility into the plant. The latter of the two ways to calculate ROI is what we will focus on in this blog.

First Ask Yourself, “What Are Your Goals?”

Getting ROI from Mingo should start from the top down. Either from the C-level or whoever is owning manufacturing; they should set the goals, the targets, the culture surrounding Mingo from the top. And then it needs to flow down the organization.

This is the same philosophy we talk about in the IIoT Guide: What are your business problems? What are you trying to solve? How are you going to solve those problems? How will your organization and culture help you solve problems?

Then, you want to make sure you’re setting up data collection and processes while creating visibility into the pre-established goals so you can easily manage it.

It’s the whole idea of “What gets measured, gets managed.” We, at Mingo, live by the idea of “If you can’t measure it, you can’t improve it.” This is the general idea of getting and proving ROI from Mingo. Throughout this blog, we’ll touch on each sub-topic in greater detail. Let’s get started.

Proving ROI Starts with Visibility

At every level, the visibility that you need to prove ROI is slightly different. If you’re the VP of Operations or CEO of a small to mid-size manufacturing company, you’re going to want summary data that tells you really, was production good or bad. Basically, this summary would tell you how the plant did yesterday, if it was good or bad, and if the numbers weren’t hit, what happened.

This information is likely pulled together with other data from sales, shipments, labor costs, raw materials, and other parts of the business to really provide that big picture.

But, as you travel down the organizational structure, people get more detail about their areas of focus. What you want to do is have different people own different parts of the process, not only creating visibility but ownership throughout the company.

You have someone who is in charge of quality. You have someone in charge of maintenance, engineering, production, scheduling, and so on. This may sound obvious, but you want to have specific goals and measurements for those folks and easily collect that data and digitize it. Then, you give each of those people a way to look at that data every day. This is, holistically, how we view Mingo.

You have targets that you want to hit every month, and it’s that person’s job to look at the detail behind those targets. Did you hit the goal? If you didn’t, why not? Or, if you did, why?

The idea is to follow this idea of ownership and goal tracking down the entire organization. Each individual has goals to accomplish that are visible, and they know how they can achieve those goals.

Standardize Accountability with Daily Meetings

This is a two-part effort. When goals are established and everyone is clear on what they need to do, you need to establish regular processes to look at that information and figure out what you can do with it. You need a plan to act on this data, good or bad.

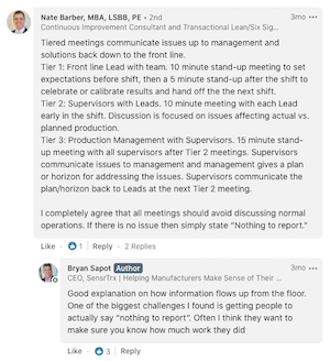

The key thing to do is to hold regular meetings. One of our partners, Nate Barber, actually summed up how to do this in a recent LinkedIn comment on Bryan Sapot’s, our CEO, posts. We couldn’t have said it better ourselves.

The idea behind it is to have 3 different meetings, each focused on a different group in the organization. These meetings allow information to flow up the hierarchy, quickly, and by using the data coming out of the system, answer the key question of “Are we hitting our goals?”

If you find that you’re not hitting the goals, you can use these meetings to understand what went right, what went wrong, and what actions you’re going to take to correct any problems. Again, this goes back to visibility and accountability.

Then, the other thing that we’ve seen lately is the concept of people focusing on areas they know have specific issues and trying to improve them. So, maybe, the cycle times are all wrong, and you know they’re all wrong, or they’re not in the system, or you know you have excess maintenance problems on a certain piece of equipment because it’s older. Using this knowledge, whoever is responsible for that area sets up a specific report or dashboard that’s emailed out to them every day or every week to understand how that certain problem did yesterday and to stop problems as they happen. Then, they use the data collected to improve that problem.

This can even include data quality standards. The report can tell you the things that were run yesterday that had no quantities associated with them or maybe jobs that ran yesterday that had no cycle times associated with them. The concept still applies – find out what happened, why it happened, and work to improve it.

Effective Culture Starts with Transparency

You have to set the goals, you have to make sure you have the right data to measure against the goals, you have to make sure that all of that information is visible at every level so everyone knows how they’re contributing to it and how they can affect those numbers. Trust us, it’s achievable.

But, the other big piece of this that we haven’t yet talked about is the cultural side.

You really have to explain, “What are we doing with the data, and why are we doing this?”

Are you doing this to find out who the underperformers are and fire them? No. That needs to be made clear throughout the organization. You’re looking for opportunities for improvement, and if there are opportunities, you’re going to work with employees to become better.

Conveying that you’re using Mingo as a means of improvement, not punishment, and to share information between employees, departments, and the entire company is imperative to get everyone on board.

5 Best Practices to Getting ROI

Once you’ve established the means to accomplish visibility, accountability, and transparency, there are 5 things we emphasize to get and prove ROI. Those 5 best practices are:

1. Create automatic daily production reports to automatically send to the supervisors and plant managers so they know how the departments, and other shifts, performed. This creates visibility and accountability.

2. Use scoreboards on the floor. These should be out on the floor so everyone can see how everyone else is doing to create and encourage a bit of competition between folks.

3. Deploy the operator screens so operators can know if they have had a good or bad day, creating engagement.

4. Set up alerts to stop problems as they happen and create awareness of things today, rather than tomorrow.

5. Integrate all of the data collected into your daily production meetings. The daily production report emails and dashboards should be utilized as much as possible. Look at real numbers and don’t talk about what the team *thinks* happened yesterday. A daily production meeting should last only 15 minutes and cover 3 questions. “Did we hit our goal? If we didn’t, why not? What can we do to ensure we hit the goal?”

Encourage Ownership of Data Specific to That Role

Data collected has to be owned by someone to find and make improvements, consistently.

Think about the operator role. As an operator, they own a particular area of production. They’re responsible for the output of their machine or line. Those numbers should be their responsibility. Of course, if there’s a maintenance issue, this is out of the operator’s hands, but at the end of the day, this is the operator’s area of responsibility.

That same thinking applies to the supervisor who oversees the entire line. They’re responsible for the numbers on the entire line for that day. They should know if they’re doing good or bad. And, this level of ownership continues to apply to each role throughout the plant.

Also, let’s not forget that someone has to own the system internally, too. From a data quality perspective, you need to have a person or a couple of people who are Mingo administrators and own the quality of the data and ensure that it’s correct. It doesn’t have to be a specialized person, and can really, be a part of someone’s already existing role, but someone needs to fulfill the responsibilities of being the Mingo administrator.

Once the system is up and running, it’s not that much work to maintain, but you need someone who is looking at this system all of the time. Filling this role is important for plant organization.

The idea behind this concept is to encourage ownership which in turn, encourages better performance. All of this rolls up to create the visibility that manufacturers really need.

Focus the Organization on the Goal and You Will See ROI

The biggest thing that happens when you follow these steps is the level of visibility you will gain. People knowing their performance is measured creates improvements. It’s called the Hawthorne Effect. And, if you put all of these processes in place, everyone in the organization knows that information. They know where the problems are coming from, and you’re more likely to get things fixed because you’re no longer relying on someone’s opinion, but hard facts.

Just doing this will provide improvements, period. It happens, we promise.

For example, if the head of maintenance has been telling you, the plant manager, for months that a particular machine repeatedly breaks down, and now has all of the data to show you that it’s actually true, you can go to the VP of Operations to get money to get it fixed or buy an entirely new machine.

Just having the visibility and knowing every day what happened, being able to look at week by week, month by month, or year by year data, and determine where the biggest losses are coming from creates that visibility that makes it possible to eliminate problems. This then creates accountability that ensures problems remain eliminated.

The best example we’ve found that illustrates this is explained in “The Goal” by Eliyahu M. Goldratt. If you haven’t read this book, we highly recommend it. When the team started staggering break schedules so they could keep a machine running, they had the data to know if this actually happened and no longer had to wait 2 days to look at the output or whip in front of it to know if it did happen. They were able to make improvements right away, all because of the data and visibility.

Really, this all comes down to focusing the team, and the organization as a whole, on what the problems are.

That is where you achieve true ROI from Mingo, through visibility and accountability into the people and processes that make your company run. In the end, this is beneficial because you can deliver on time to your customers and make money, which for all manufacturers, is the end goal.