Knowing the differences between the terms is only half the battle. It’s also important to know which ones you should use and when. This is where it’s essential to understand what you’re actually measuring and why.

Most people think cycle time is actually the same as the machine cycle (again, throwing out more terms, but it’s important to understand what you’re measuring), but a machine cycle does not represent the entirety of a process. It’s more important to look at the complete process (aka looking beyond just the machine cycle). This includes the time it takes for an operator to load a job, the time and effort it takes to get the machine up and running, unloading the part or adding finishing touches by hand once the part has been made.

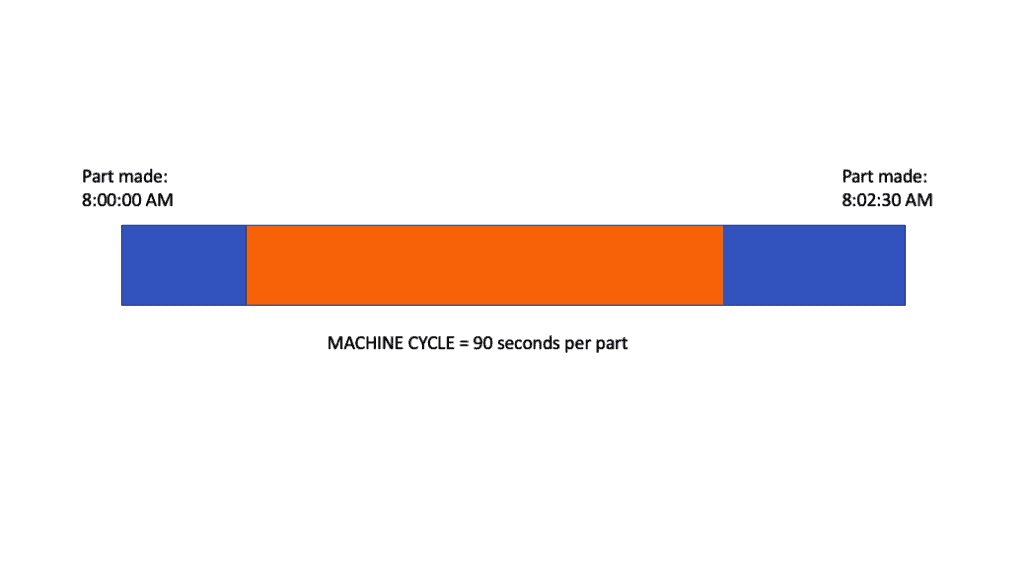

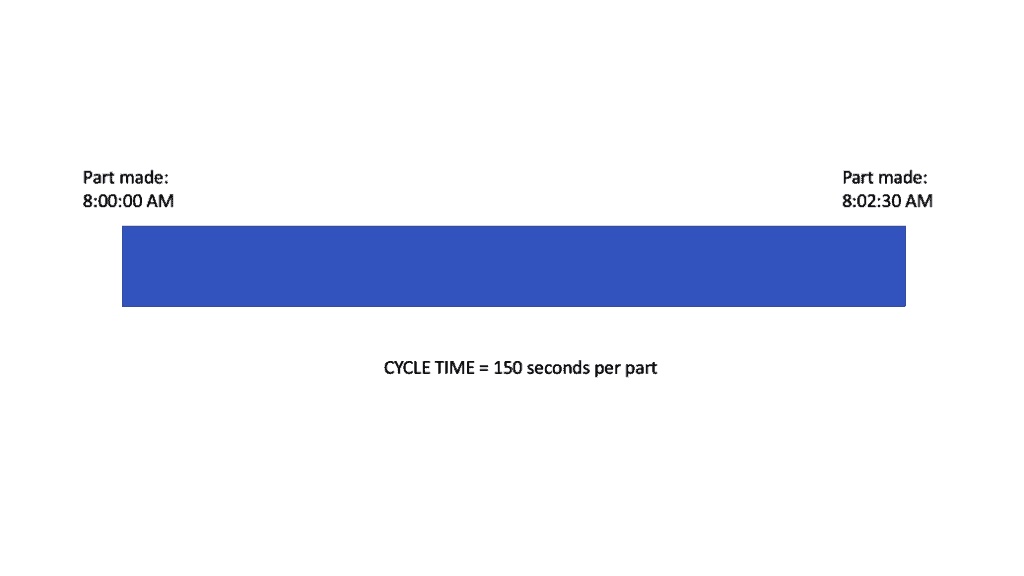

The images below provide a visual representation of why measuring the cycle time of a process is more valuable than measuring just the machine cycle.

The orange portion for example #1 is likely what you, and many other manufacturers, think represents the cycle time. You could make 200 parts, but you probably didn’t take into account the manual actions the operator needs to do to get it up and running in the first place. If that’s the case, you will have over-estimated the amount of product that can be made in a given period.

It’s important to look at the process in a way that includes all factors, not just the making of a product by a machine which is where example #2 comes into play.

Example #2 is good for making estimates because it shows how fast you are capable of running (from start to finish), and will, in turn, give you a target cycle time that is easier to hit and measure. Then, you can use that number to calculate how much product you’re actually making and if there are problems or issues that need addressing.

Let’s be the devil’s advocate for a moment. Some manufacturers may only want to look at the machine cycle. Specifically, how close are you getting to removing the blue parts of this cycle? Not to sound repetitive, but this severely limits your ability to measure the process as a whole.

Do you want to measure the time it takes to produce just the part in the machine (machine cycle) or the entirety of the process to determine what’s actually possible (cycle time)? If you said the latter, yes, that’s what would recommend, too.

At this point, you likely know which metric we believe in measuring, but for the sake of driving the point home, we suggest measuring the entirety of the cycle and referring to that as the ideal cycle time.