Automotive manufacturing got its start at the turn of the 20th century. In 1900, Ransom E. Olds began manufacturing the Oldsmobile in Detroit. While he would go on to produce about 25,000 cars and go bankrupt only 6 years later, his business effectively created the automotive industry. Since then, mobility has vastly grown, changing as our economy has evolved. Today, manufacturers are experiencing Industry 4.0, a time of mass technological evolution that presents a new opportunity with automotive software.

Automotive manufacturers are faced with unique challenges that while difficult, provide an opportunity to reinvigorate the industry with smart technology. The impact of Industry 4.0, big data, and automotive software like Mingo provide the ability for businesses to scale and grow.

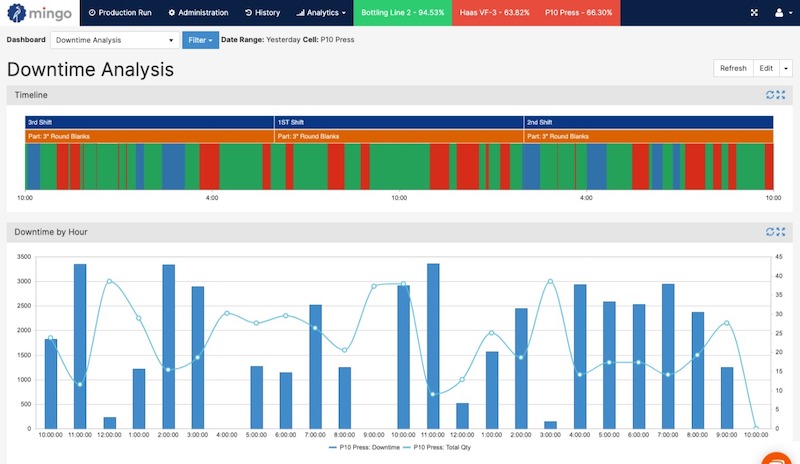

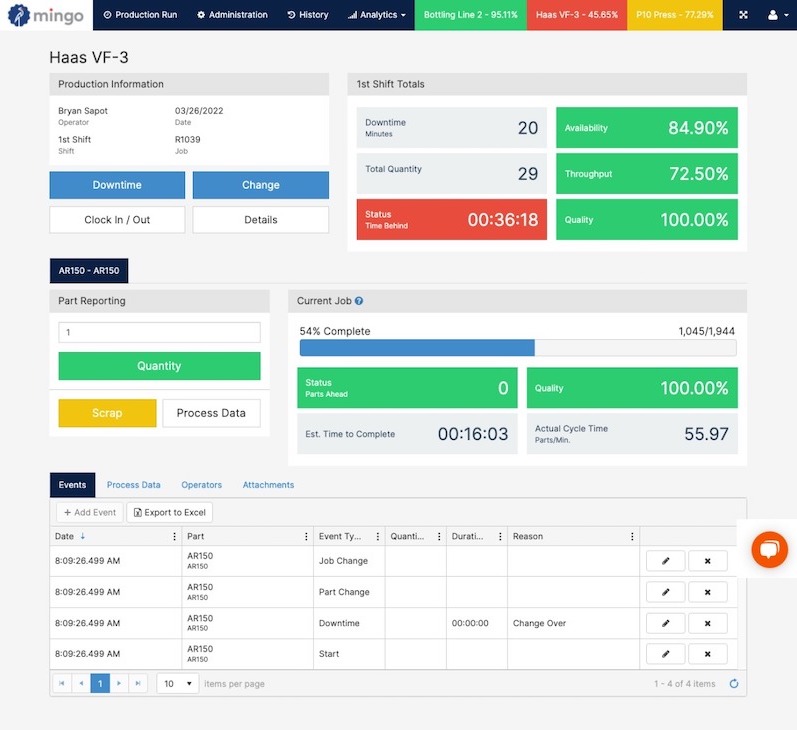

It’s very likely you have an abundance of data due to stringent quality requirements mandated by recall legislation, but what if you could use that data for productivity improvements, too? With automotive software, you can gain visibility into areas you succeed in and areas for improvement that give you the ability to make informed decisions, actively track your machines for continuous improvement, find potential problems before they cause additional issues, and practice predictive analysis.