There’s no question – food and beverage manufacturing is changing rapidly. With the rise of Industry 4.0, the new buzzword on everyone’s mind is “big data“. But, what do you do with it, and how does it apply to the food manufacturers, beverage manufacturers, or even pet food manufacturers?

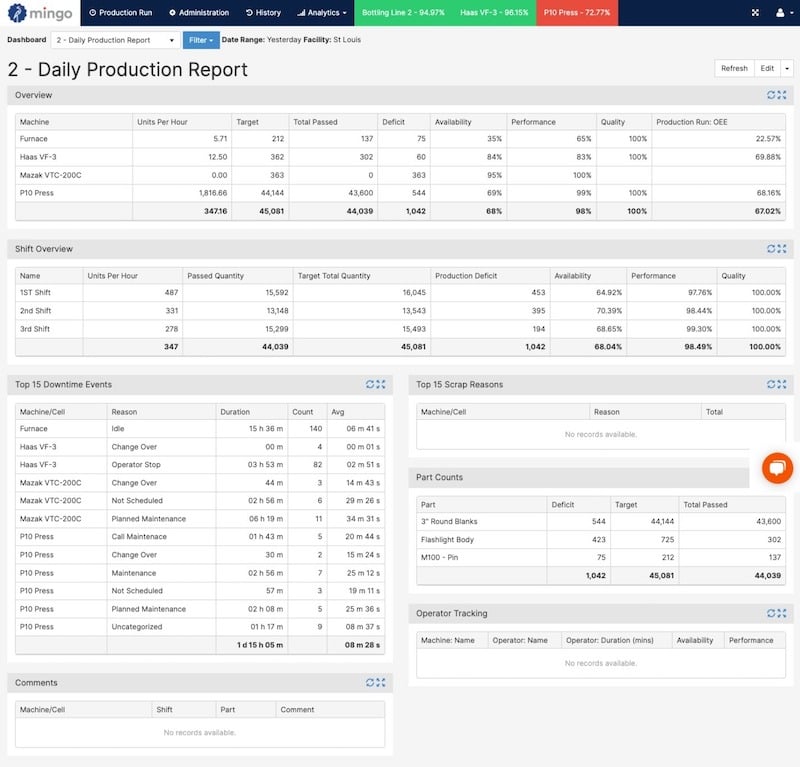

Each food and beverage manufacturer has unique safety, regulatory, and customer requirements that must be fulfilled. Tracking those requirements accurately, and in real-time, provides the biggest benefit for meeting standards and continuous improvement. Good data management is now essential for accurately tracking and linking all products to a specific source or batch.

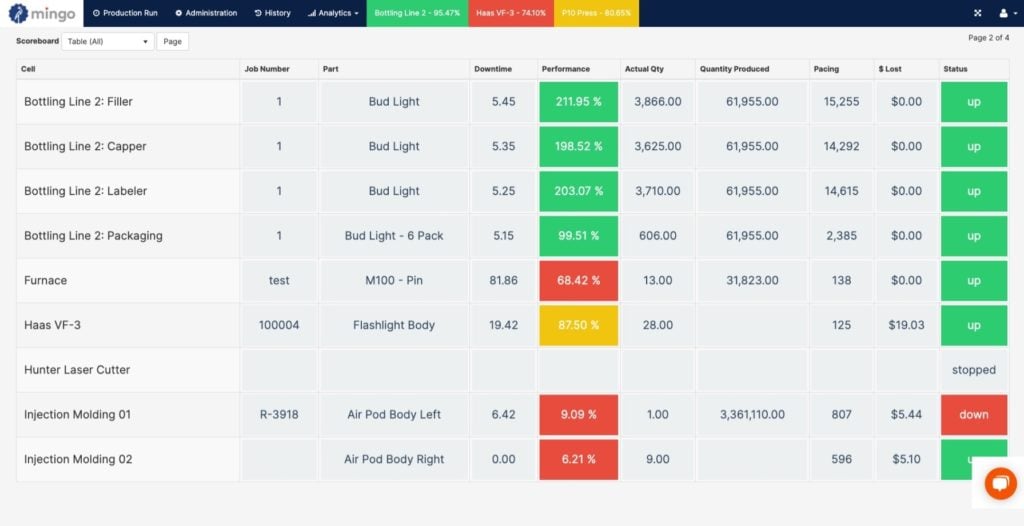

In the food processing industry, quality, yield, headcount, labor units per hour, and units per hour produced are all important metrics. Food and beverage software can help provide actionable insights into the production process and help to ensure all standards, including quality and yield, are met.